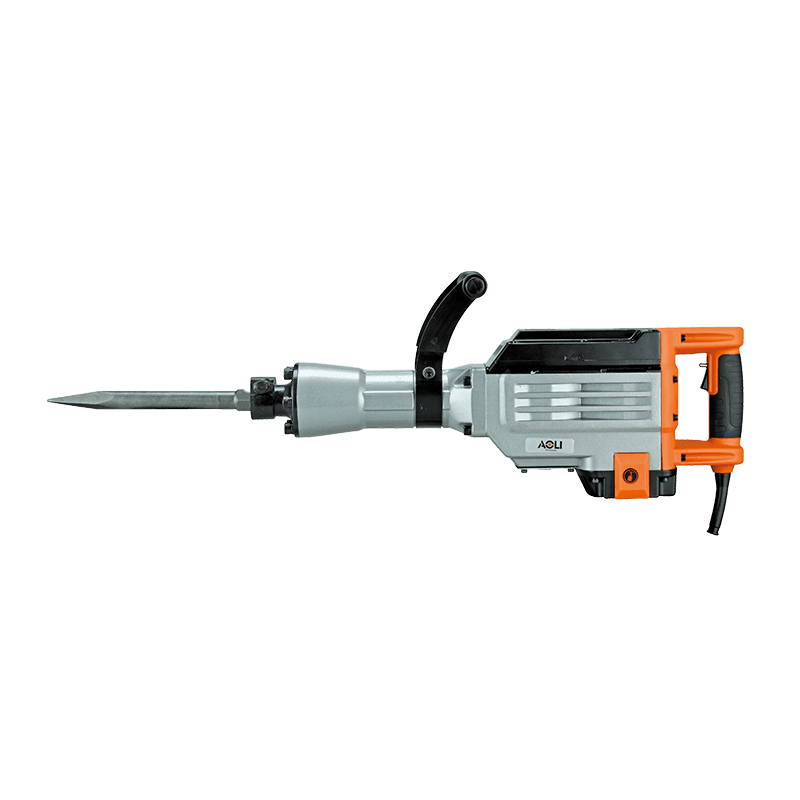

Sale High-Quality Jack Chipping Hammer Drill Wholesaler

In the construction arena, the comfort of operators is a critical consideration, and the tools they wield play a pivotal role. This article delves into the nuanced differences in vibration and noise control performance between Jack Hammer and Chipping Hammer Drill, examining how these aspects impact the overall comfort and well-being of operators.

The inherent force of a jackhammer brings with it significant vibrations. This section explores how the powerful blows delivered by a jackhammer can generate substantial vibrations, potentially causing discomfort and fatigue for operators. Despite its efficiency in material removal, the impact force also contributes to heightened vibration levels during operation.

Chipping Hammer Drill, designed for precision work, offers a different vibration control dynamic. This section delves into how its controlled impact, often resulting in lower force compared to a jackhammer, translates into reduced vibrations. The emphasis on precision work also contributes to a more controlled and comfortable operational experience for the user.

Operator comfort is paramount in any construction task. This section discusses how the vibrational disparities between Jack Hammer and Chipping Hammer Drill can impact operator comfort. It explores the potential for operator fatigue, hand-arm vibration syndrome (HAVS), and discomfort associated with prolonged use of tools generating higher vibrations.

While the Jack Hammer boasts sturdy power, this section analyzes how its sheer force may come at the expense of operator comfort. The ergonomic considerations, including handle design and anti-vibration features, play a crucial role in mitigating the impact on operators. Balancing power with operator well-being becomes a key aspect in selecting and using Jack Hammer effectively.

In contrast, Chipping Hammer Drill's ergonomic design takes center stage in promoting operator comfort. This section explores how the tool's lighter weight, adjustable handles, and anti-vibration features contribute to a more comfortable and controlled user experience. These ergonomic considerations enhance the precision work capability without sacrificing the comfort of the operator.

The noise generated during operation is another significant factor. Jack Hammer, with its powerful blows, often produces a distinct roar. This section delves into how the noise levels of a Jack Hammer can be higher, potentially leading to challenges in communication on the construction site and, over time, impacting operator hearing health.

Chipping Hammer Drill, designed for precision and controlled tasks, tends to produce less noise during operation. This section examines how its quieter operation contributes to a more conducive and less disruptive work environment. The subdued sound levels enhance communication on the job site and reduce the risk of noise-related fatigue for operators.

Effective communication on a construction site is crucial for safety and efficiency. This section explores how the noise and vibration control disparities between Jack Hammer and Chipping Hammer Drill can impact communication dynamics. A harmonious blend of powerful yet controlled tools becomes imperative to maintain seamless coordination among the construction team.

Operator training is a key aspect in mitigating the potential risks associated with vibrations and noise. This section discusses how educating operators about the tools they use, emphasizing proper handling techniques, and promoting awareness about potential risks can contribute to a safer and more comfortable work environment.

Advancements in technology play a role in shaping more comfortable tool designs. This section explores how manufacturers are incorporating innovative features, such as anti-vibration systems, noise reduction technologies, and ergonomic enhancements, to prioritize operator comfort without compromising the tools' operational efficiency.

English

English Español

Español русский

русский