China Design Jack Chipping Hammer Drill Manufacturing Factory

In the dynamic field of construction, the choice between Jack Hammer and Chipping Hammer Drill is pivotal, each serving distinct roles in specific applications. This article delves into the nuanced differences in their primary uses, shedding light on how these powerful tools contribute uniquely to construction projects.

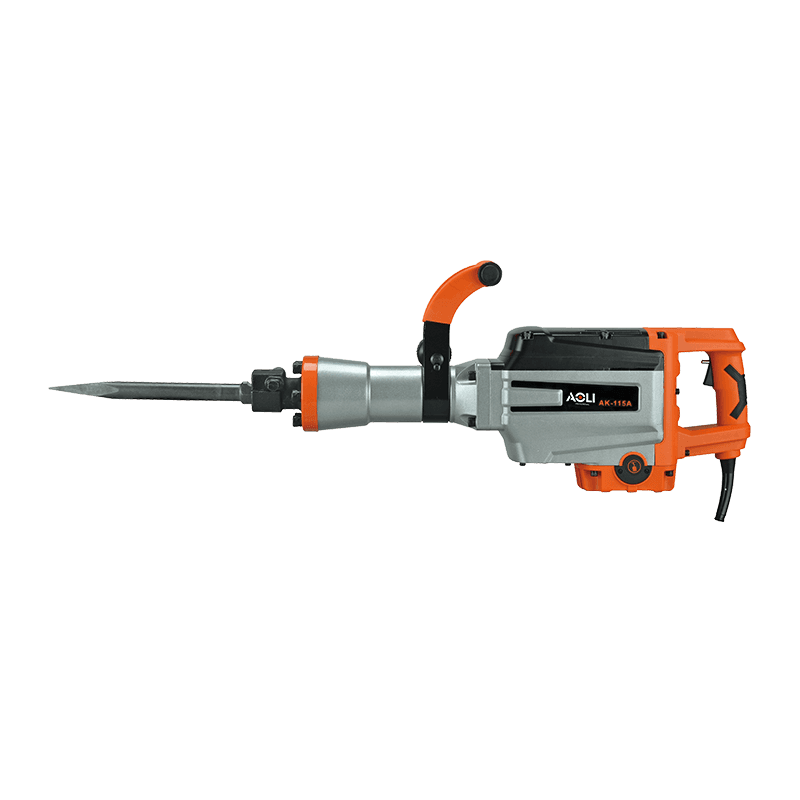

The Jack Hammer stands as a symbol of raw power in construction. Its primary purpose revolves around demolition tasks, breaking through tough surfaces like concrete and asphalt effortlessly. Its pneumatic or electric operation delivers high-impact blows, making it indispensable in scenarios demanding forceful material removal.

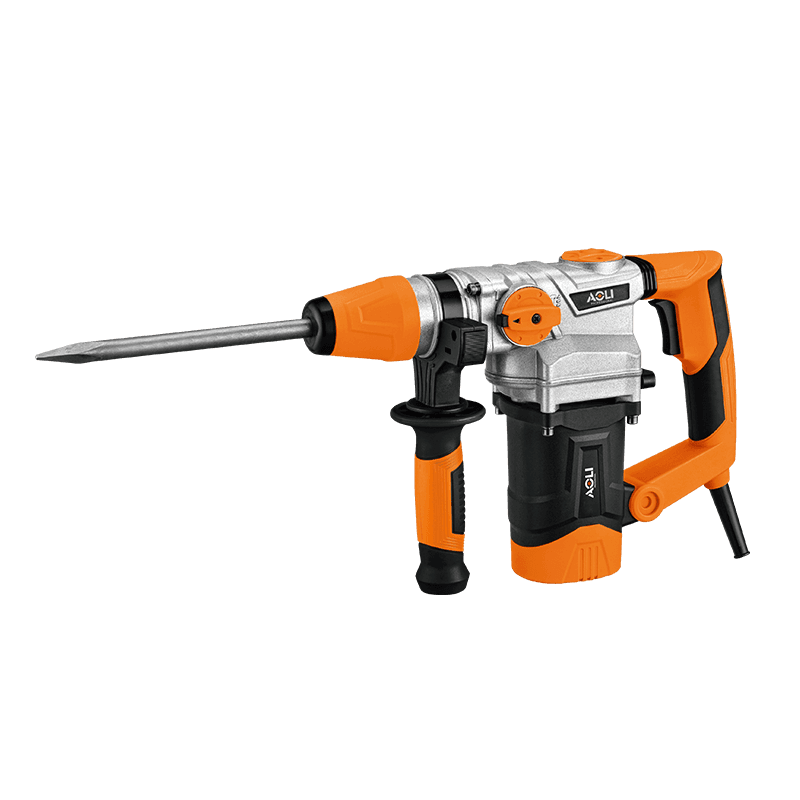

In contrast, the Chipping Hammer Drill emerges as a tool of precision in material removal. This section explores how the Chipping Hammer Drill excels in controlled chiseling and drilling tasks. With a more targeted impact, it is ideal for applications that demand finesse, allowing for intricate work on surfaces without compromising structural integrity.

The Jack Hammer's dominance in demolition tasks cannot be overstated. This section details its unparalleled efficiency in breaking down large structures, such as walls, pavements, or foundations. Its forceful blows, delivered through a variety of chisel attachments, make it a tool for quick and effective material removal in demolition scenarios.

Chipping Hammer Drill, on the other hand, finds its niche in precision chiseling. This section examines how it's controlled impact and versatile chisel attachments make it suitable for intricate tasks like removing tile, shaping stone, or chiseling away specific sections of concrete. Its ability to operate in confined spaces adds to its appeal in projects demanding finesse.

Beyond demolition, the Jack Hammer's versatility extends to a wide range of construction applications. This section explores how it can be used for tasks such as digging, trenching, and breaking up hardened soil. Its adaptability to different attachments allows it to tackle diverse challenges across construction sites, showcasing its multifunctional prowess.

The Chipping Hammer Drill, while not as versatile as the Jack Hammer, excels in focused drilling tasks. This section delves into its proficiency in drilling holes for anchors, bolts, or small conduits. Its controlled drilling capabilities make it an ideal choice for tasks where precision and accuracy are paramount, emphasizing quality over sheer force.

The Jack Hammer's impact is not just in its force but also in its operational dynamics. This section examines how its pneumatic or electric operation, coupled with ergonomic designs, allows for extended use without excessive fatigue. This ensures that operators can maintain efficiency even during prolonged demolition tasks.

While the Chipping Hammer Drill may lack the sheer force of the Jack Hammer, its ergonomic design shines in precision applications. This section highlights how its lighter weight and ergonomic features contribute to operator comfort, enabling sustained performance in tasks that demand attention to detail.

Safety is paramount in construction, and this section explores the safety considerations associated with both tools. It discusses measures such as the use of personal protective equipment (PPE), proper training, and adherence to safety guidelines to mitigate risks associated with the high-impact nature of both the jackhammer and Chipping Hammer Drill.

Ultimately, the choice between the jackhammer and Chipping Hammer Drill depends on the specific requirements of the construction project. This section guides factors such as project scale, material type, and the level of precision needed to help contractors make informed decisions when selecting the appropriate tool for the task at hand.

English

English Español

Español русский

русский