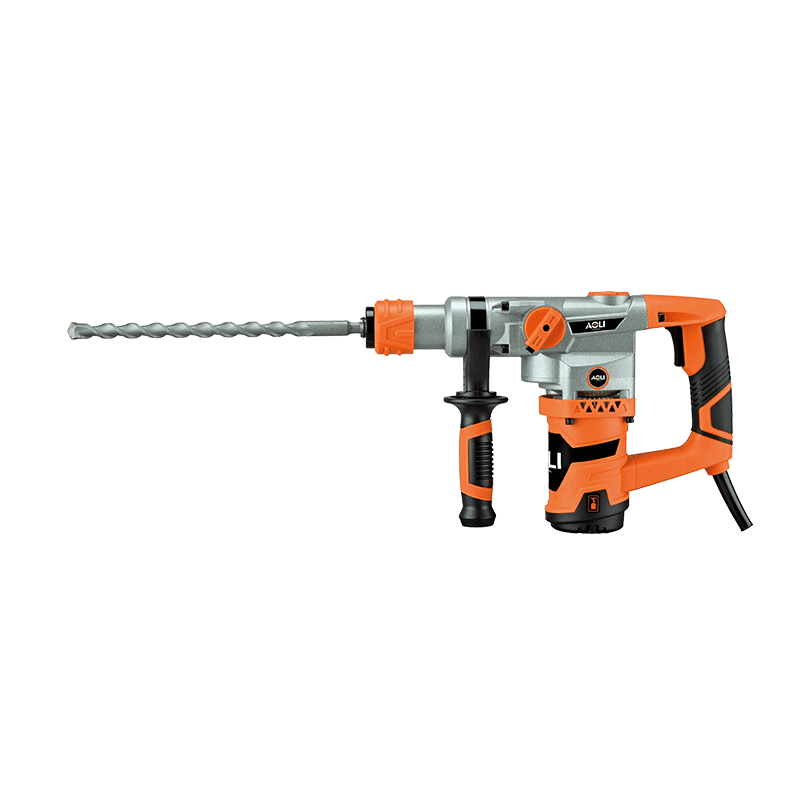

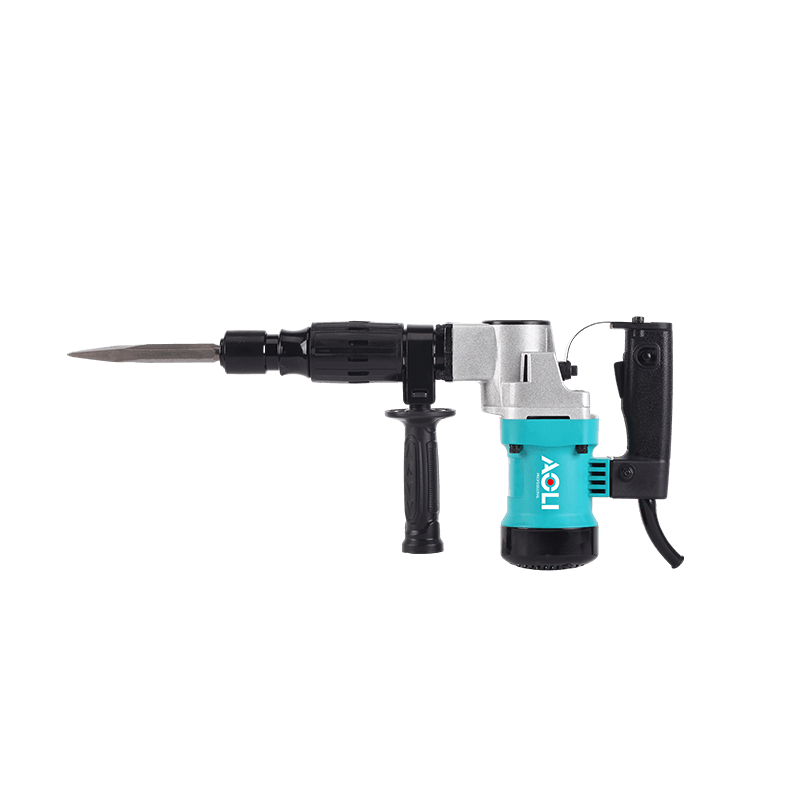

Wholesale China High-Speed Chipping Hammer Drill Company

In the realm of industrial equipment, China Chipping Hammer Drill has emerged as an indispensable tool for various applications, ranging from construction and demolition to mining and metalworking. As global awareness of environmental issues continues to grow, manufacturers of China Chipping Hammer Drills are increasingly prioritizing environmental considerations in their design, production, and operation processes. By adopting sustainable practices, materials, and technologies, China Chipping Hammer Drill manufacturers are striving to decrease their environmental footprint and promote a greener, more sustainable future.

One of the primary environmental considerations in China's Chipping Hammer Drill manufacturing is the reduction of energy consumption and emissions. Traditional pneumatic Chipping Hammer Drills rely on compressed air for operation, which can be energy-intensive and generate significant noise pollution and air emissions. To address these challenges, manufacturers are developing electric-powered Chipping Hammer Drills that offer lower energy consumption, reduced emissions, and quieter operation. By transitioning towards electric power sources, China Chipping Hammer Drill manufacturers can reduce their environmental impact while improving the working conditions for operators and surrounding communities.

Moreover, advancements in battery technology are driving the development of cordless electric Chipping Hammer Drills, further enhancing sustainability and portability. Lithium-ion batteries, in particular, offer high energy density, fast charging capabilities, and extended runtime, making them ideal power sources for cordless Chipping Hammer Drills. With cordless electric models, operators can work more flexibly without relying on fossil fuels or emitting harmful pollutants, reducing their environmental footprint and promoting cleaner, more sustainable operations.

In addition to reducing energy consumption and emissions, China Chipping Hammer Drill manufacturers are exploring ways to reduce

waste and promote recycling and reuse throughout the product lifecycle. By incorporating lightweight yet durable materials such as aluminum alloys and composite plastics, manufacturers can reduce the overall weight of Chipping Hammer Drills while maintaining performance and durability. Furthermore, designing Chipping Hammer Drills for disassembly and component reuse at the end of their service life can facilitate recycling and decrease waste generation, contributing to a circular economy and reducing environmental impact.

Furthermore, China Chipping Hammer Drill manufacturers are implementing design improvements and technology innovations to enhance sustainability and resource efficiency. Lightweight materials, ergonomic designs, and advanced cooling systems help reduce energy consumption, reduce operator fatigue, and prolong equipment lifespan. Additionally, intelligent control systems and onboard diagnostics enable operators to monitor performance, identify inefficiencies, and optimize operations for efficiency and environmental impact.

Moreover, China Chipping Hammer Drill manufacturers are investing in research and development to explore alternative energy sources and propulsion systems that offer even greater sustainability and environmental benefits. Hybrid Chipping Hammer Drills that combine electric and pneumatic power sources, as well as renewable energy-powered models, are being developed to further reduce reliance on fossil fuels and reduce greenhouse gas emissions. Additionally, advancements in regenerative braking and energy recovery systems could enable Chipping Hammer Drills to capture and reuse energy during operation, further enhancing sustainability and resource efficiency.

In conclusion, China Chipping Hammer Drill manufacturers are making significant strides in integrating environmental considerations into their design, production, and operation processes. By prioritizing energy efficiency, emissions reduction, waste, and resource efficiency, manufacturers are not only reducing their environmental footprint but also promoting a more sustainable and eco-friendly industry. Through continued innovation and collaboration, China Chipping Hammer Drill manufacturers can drive positive environmental change and contribute to a cleaner, greener future for generations to come.

English

English Español

Español русский

русский