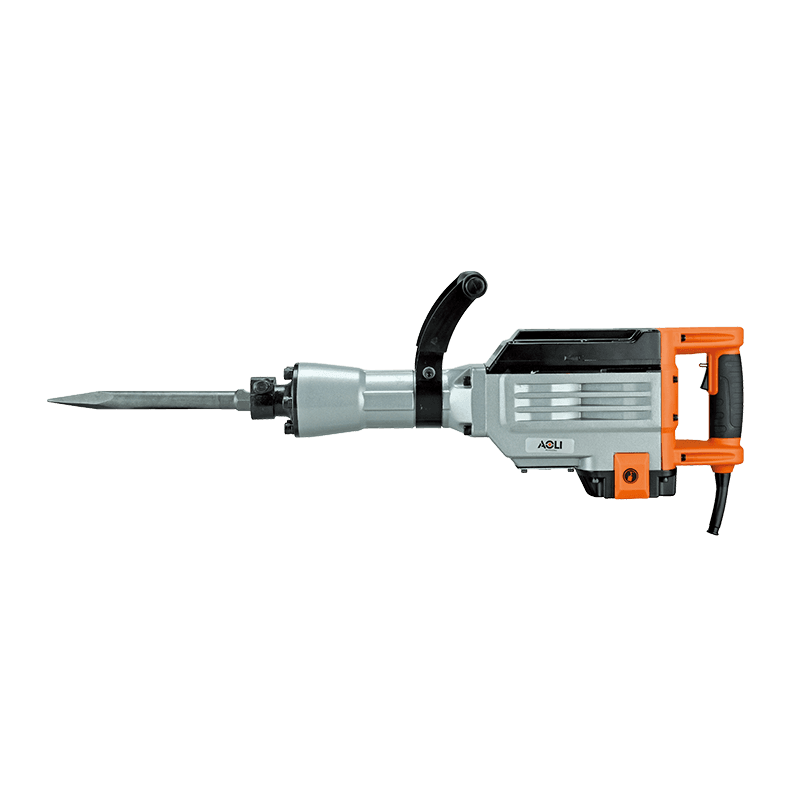

When it comes to rotary hammer tools, understanding the distinction between hammer drill frequency and power is crucial for achieving optimal performance and efficiency in drilling applications. Both factors play significant roles in determining the tool's effectiveness and suitability for various tasks. In this article, we'll explore the differences between hammer drill frequency and power in rotary hammer tools, shedding light on their importance and impact on drilling performance.

Hammer drill frequency refers to the rate at which the hammer mechanism delivers impacts to the drill bit during operation. It is measured in blows per minute (BPM) and indicates how rapidly the drill bit strikes the material being drilled. The hammer drill frequency directly affects the tool's ability to penetrate hard materials such as concrete, masonry, and stone efficiently.

1. Impact Force: The hammer drill frequency determines the impact force exerted by the drill bit on the material surface. Higher frequencies result in more frequent and forceful impacts, allowing the drill bit to break through tough materials more effectively.

2. Speed of Drilling: A higher hammer drill frequency enables faster drilling speeds, as the drill bit can deliver more impacts per minute. This is particularly beneficial when drilling into dense or thick materials, as it reduces the overall drilling time and increases productivity.

3. Enhanced Chiseling Performance: In addition to drilling, rotary hammer tools with high hammer drill frequencies excel in chiseling applications. The rapid and repetitive impacts generated by the hammer mechanism enable efficient chiseling and shaping of materials, making them ideal for tasks such as tile removal and surface preparation.

Power refers to the rotary hammer tool's overall ability to generate and deliver torque and force to the drill bit during operation. It is measured in watts (W) or horsepower (HP) and encompasses various factors, including motor strength, drive system efficiency, and overall build quality.

1. Motor Strength: The power of a rotary hammer tool is largely determined by the strength and capacity of its motor. High-power motors can deliver greater torque and rotational force to the drill bit, enabling it to overcome resistance and penetrate tough materials more easily.

2. Drive System Efficiency: The efficiency of the drive system, including the transmission of power from the motor to the drill bit, also influences the tool's overall power. A well-designed drive system minimizes energy loss and ensures the transfer of power to the drill bit, resulting in enhanced drilling performance.

3. Versatility and Durability: Rotary hammer tools with high power ratings are often more versatile and durable, capable of handling a wide range of drilling tasks and operating in demanding conditions. They can withstand heavy use and prolonged operation without compromising performance or reliability.

While hammer drill frequency and power are distinct parameters, they are closely related and often work together to determine the overall effectiveness of a rotary hammer tool. A tool with high hammer drill frequency and power can deliver rapid, forceful impacts to the drill bit, resulting in efficient drilling performance and enhanced productivity.

For example, a high-power rotary hammer tool with a robust motor and efficient drive system can generate sufficient torque and rotational force to drive the drill bit at a high frequency, resulting in rapid and effective drilling through tough materials. Conversely, a tool with lower power may struggle to maintain high hammer drill frequencies, resulting in slower drilling speeds and reduced efficiency.

The hammer drill frequency and power are essential factors that influence the performance and effectiveness of rotary hammer tools in drilling applications. While hammer drill frequency determines the rate of impact delivered to the drill bit, power dictates the overall torque and force generated by the tool. By understanding the differences between these parameters and selecting rotary hammer tools with appropriate frequency and power ratings, users can achieve optimal drilling performance and efficiency in a variety of construction and renovation tasks.

English

English Español

Español русский

русский