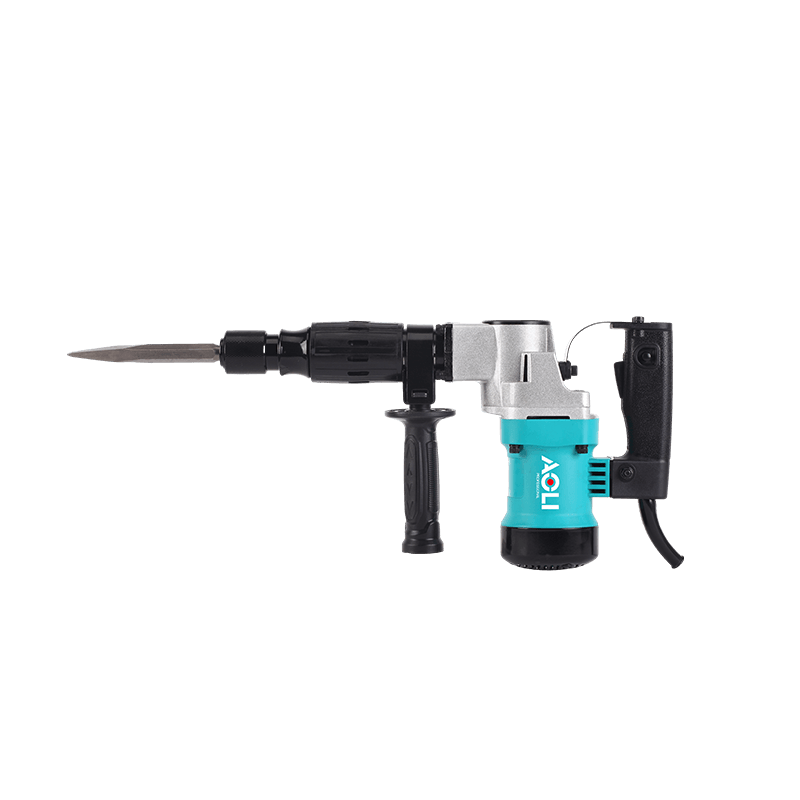

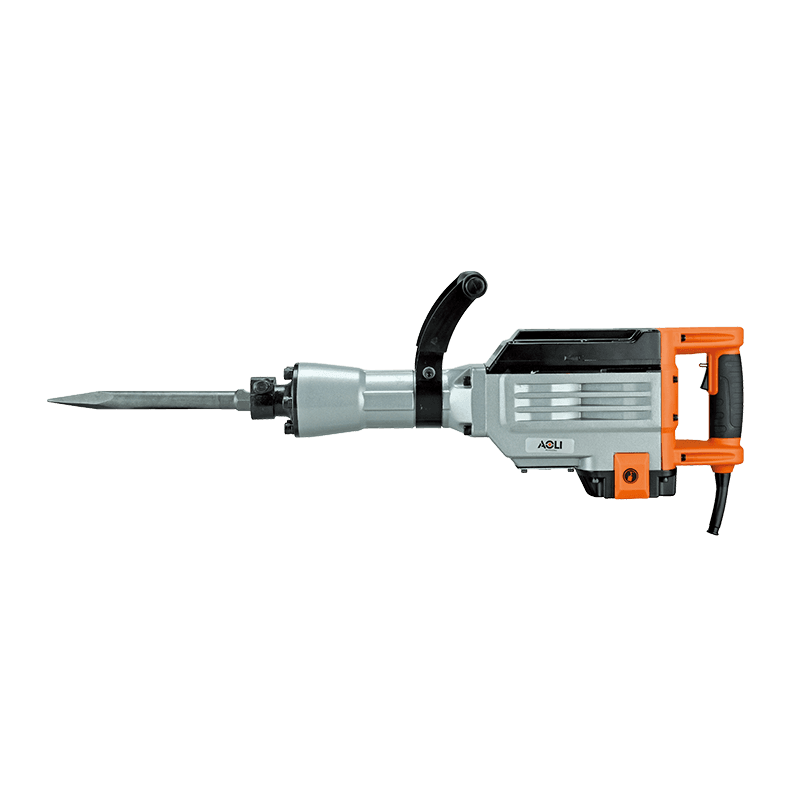

Air tool hammers, commonly known as pneumatic rotary jackhammers, are widely used in construction, mining, and demolition industries. A well-designed pneumatic rotary jackhammer can greatly enhance work efficiency and reduce fatigue for the users. In this article, we will explore the importance of user-friendly design in pneumatic rotary jackhammers and discuss various features that make them ergonomic and comfortable to use.

1. Lightweight and Compact Design:

One of the key aspects of a user-friendly pneumatic rotary jackhammer is its lightweight and compact design. The tool should be easy to handle and maneuver. A lightweight design reduces user fatigue and allows for longer periods of use without strain. Additionally, a compact design ensures that the tool can be used in tight spaces and confined areas.

2. Vibration Dampening System:

Excessive vibration is a common concern with pneumatic rotary jackhammers and can lead to hand-arm vibration syndrome (HAVS). A user-friendly design should incorporate a vibration dampening system to minimize the impact on the user's hands and arms. This can be achieved through the use of anti-vibration handles or advanced damping technologies, ensuring operator comfort and safety.

3. Ergonomic Handle:

The handle of a pneumatic rotary jackhammer plays a critical role in user comfort and control. An ergonomic handle design that fits comfortably in the user's hand reduces fatigue and allows for better grip and leverage. It should be designed to minimize hand and wrist strain, enabling extended periods of use without discomfort.

4. Adjustable Auxiliary Handle:

A user-friendly pneumatic rotary jackhammer should include an adjustable auxiliary handle. This feature allows the user to customize the grip position according to their preferences and working conditions. It enhances user control and reduces strain on the user's arms and shoulders, ensuring a more comfortable and efficient working experience.

5. Noise Reduction Measures:

Noise is another important factor to consider when designing a user-friendly pneumatic rotary jackhammer. Excessive noise can be harmful to the user's hearing and can also cause fatigue and stress. The tool should be equipped with noise reduction features such as insulation materials, mufflers, or soundproof casings to minimize noise levels and provide a safer and more comfortable working environment.

6. Trigger Lock Mechanism:

A pneumatic rotary jackhammer should also be equipped with a trigger lock mechanism. This feature allows the user to lock the tool in the on position, reducing the need for constant gripping and finger fatigue. It provides convenience and comfort, especially during prolonged periods of use.

7. Accessibility and Ease of Operation:

A well-designed pneumatic rotary jackhammer prioritizes accessibility and ease of operation. Ergonomic features, such as conveniently located switches, controls, and adjustable depth gauges, ensure that users can make quick adjustments without excessive effort or strain. Additionally, intuitive and easy-to-understand operating instructions contribute to a smoother user experience, allowing even less experienced operators to efficiently use the tool.

A user-friendly design is essential for pneumatic rotary jackhammers to enhance user comfort, safety, and productivity. Lightweight and compact designs, vibration dampening systems, ergonomic handles, adjustable auxiliary handles, noise reduction measures, and trigger lock mechanisms are all key features that contribute to a tool's user-friendliness. By prioritizing these design elements, manufacturers can ensure that their pneumatic rotary jackhammers are not only efficient and powerful but also comfortable and ergonomic for the operators to use.

English

English Español

Español русский

русский