In the realm of electrical hand tools, two commonly used instruments stand out for their versatility and efficiency: electric picks and electric hammers. Despite sharing similarities in their functionality and applications, these tools possess distinct characteristics that cater to different needs and preferences. With our strong R&D team, we are committed to developing and producing high-quality products that meet the unique requirements of our customers, ensuring performance and reliability in various tasks and industries.

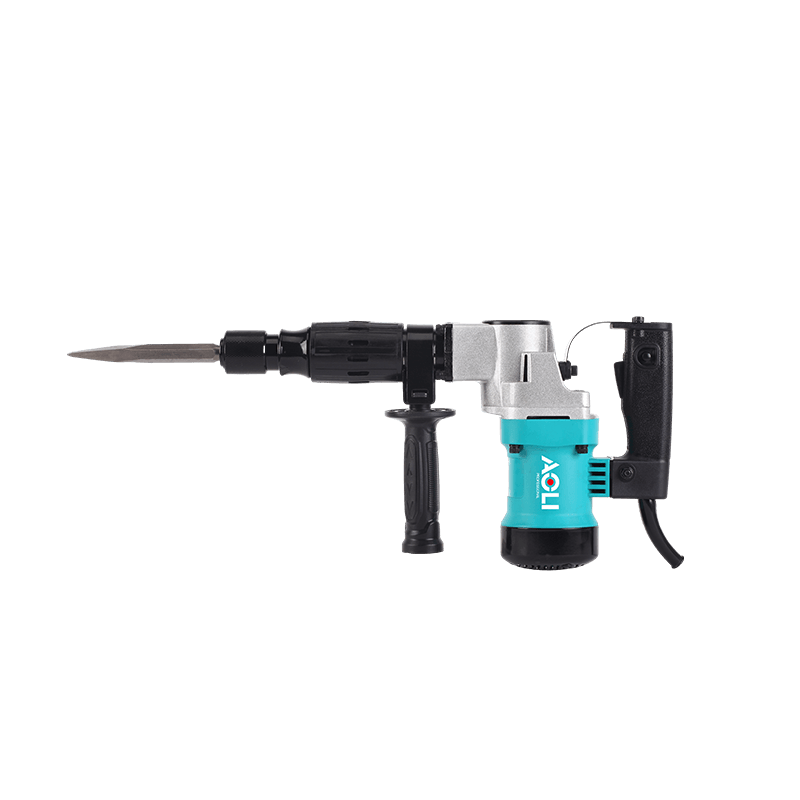

Electric Picks:

Electric picks, also known as electric chipping hammers or chisel hammers, are precision tools designed for detailed and intricate work. Unlike their larger counterparts, which are primarily used for heavy-duty demolition and breaking tasks, electric picks are smaller in size and more maneuverable, making them ideal for tasks that require precision and control. Equipped with a chisel-like tip, electric picks excel in chipping away small sections of material, carving intricate designs, and removing mortar or tile grout.

Key Features of Electric Picks:

1. Precision Chiseling: Electric picks offer precise control over chiseling depth and direction, allowing users to achieve intricate details and fine finishes.

2. Maneuverability: Their compact size and lightweight design make electric picks easy to maneuver in tight spaces and hard-to-reach areas.

3. Versatility: Electric picks are suitable for a wide range of applications, including sculpting, engraving, tile removal, and surface preparation.

4. Reduced Vibrations: Advanced vibration damping technology minimizes hand fatigue and discomfort during prolonged use, enhancing user comfort and productivity.

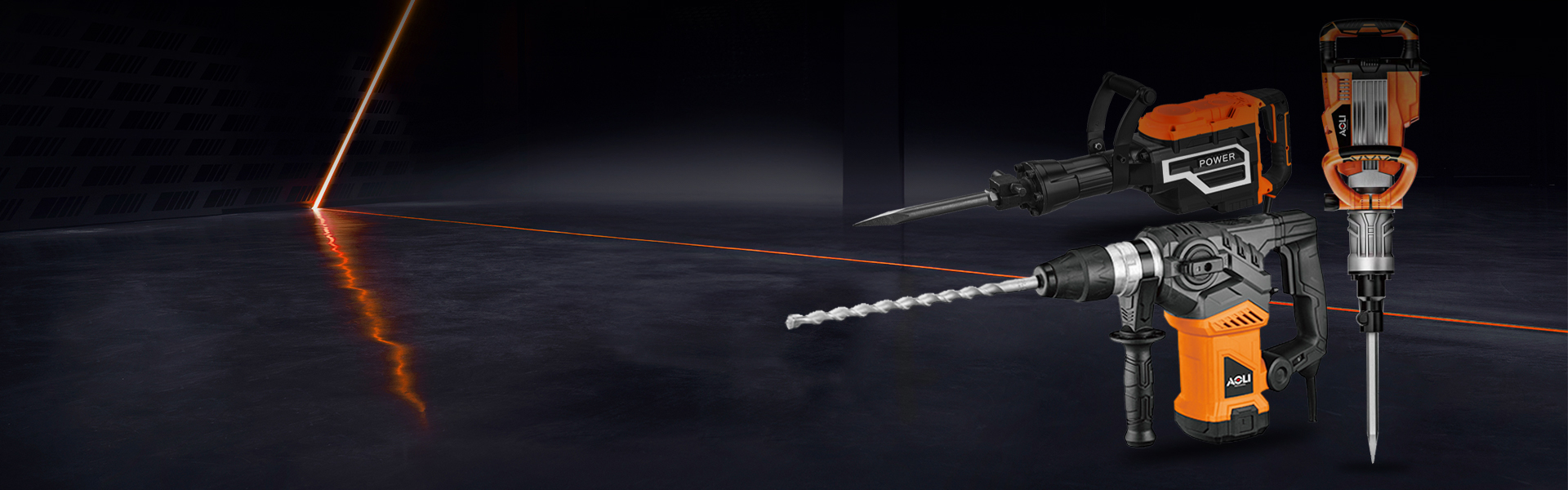

Electric Hammers:

In contrast, electric hammers, also referred to as rotary hammers or demolition hammers, are heavy-duty tools designed for tackling tough materials and demanding tasks. Featuring a pneumatic hammering mechanism, electric hammers deliver rapid and powerful blows to break through concrete, brick, stone, and other hard surfaces. These versatile tools are essential in construction, renovation, and demolition projects, where efficiency and productivity are paramount.

Key Features of Electric Hammers:

1. High-Impact Performance: Electric hammers deliver high-impact blows with exceptional force, allowing users to quickly and effectively break through tough materials.

2. Versatility: With interchangeable chisel heads and adjustable settings, electric hammers can perform a variety of tasks, including drilling, chiseling, and demolition.

3. Power and Efficiency: Equipped with robust motors and advanced hammering mechanisms, electric hammers offer unmatched power and efficiency, enabling users to complete tasks swiftly and with minimal effort.

4. Durability: Constructed from high-quality materials and engineered for durability, electric hammers are built to withstand the rigors of heavy-duty use in demanding environments.

In summary, electric picks and electric hammers represent two distinct categories of electrical hand tools, each tailored to specific applications and requirements. While electric picks excel in precision chiseling and detail work, electric hammers are indispensable for heavy-duty demolition and breaking tasks. By understanding the differences between these tools and their respective features and capabilities, users can select the most suitable tool for their needs, whether it's carving intricate designs, removing stubborn materials, or breaking through solid surfaces. With our commitment to innovation and quality, we strive to provide customers with reliable and efficient electrical hand tools that empower them to achieve their goals with confidence and precision.

English

English Español

Español русский

русский