A corded power hammer is a common tool used in a variety of construction and renovation projects. As a frequently used power tool, the condition of the power cord is very important to its normal operation and service life. The following will introduce some methods to determine whether the power cord of a wired power hammer needs to be replaced, and share some processing experience in product production and use.

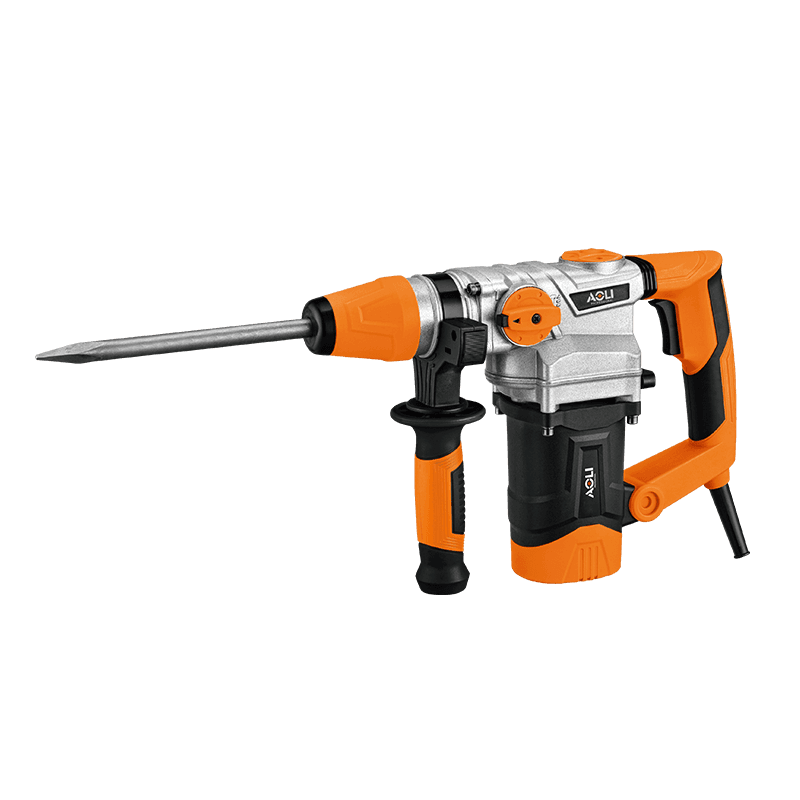

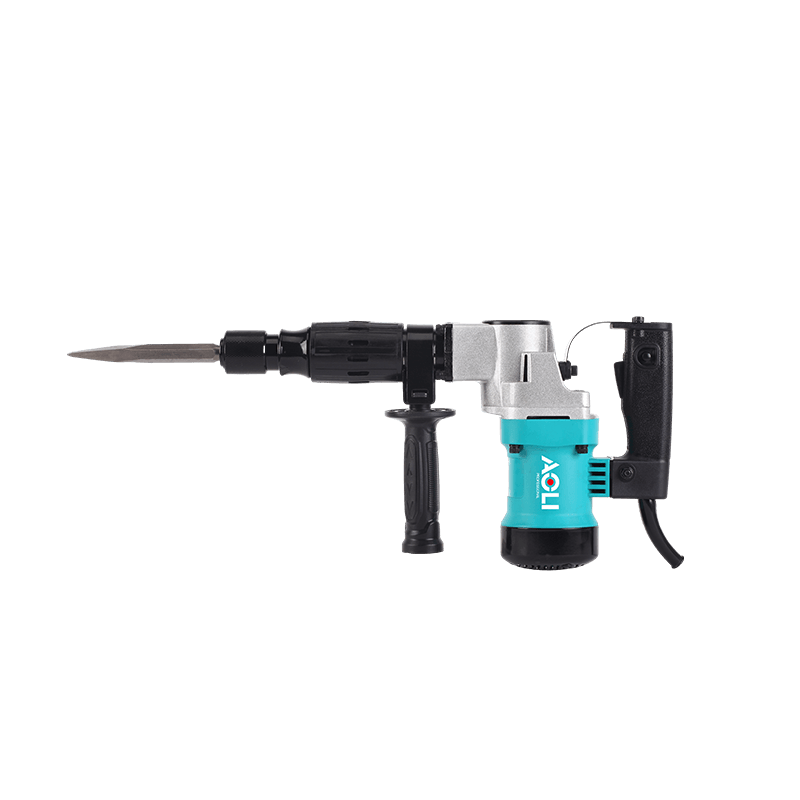

First, you need to carefully examine the appearance of the power cord. When you see obvious damage, cracks, or breaks in the insulation of your power cord, it’s time to replace it. This condition may be caused by prolonged use, frequent bending, or wear and tear from debris. Corded Rotary Hammers require frequent movement and manipulation during use, so the cord is susceptible to damage. Once the insulation layer is found to be damaged, stop using it immediately and contact a professional technician to replace the power cord.

Pay attention to the connection part of the power cord. The place where the power plug and the tool body are connected is a place where malfunctions can easily occur. If problems such as a loose plug, poor contact, or exposed wire ends are found, the power cord needs to be tightened or replaced. In Power Rotary Hammers, the connection of the power plug and power cord is very important, any looseness may cause unstable current or power interruption.

Pay attention to whether the power cord is twisted or kinked. When the power cord is often bent and twisted during use, it may cause the copper wire inside the wire to separate from the insulation layer, thus affecting the current transmission effect. Therefore, you should avoid frequently forcibly twisting the power cord and try to keep it in a natural and straight state. If you find that the power cord is often kinked or twisted, it's best to take steps to resolve the problem before replacing the cord.

In addition to the above indicators, some handling experiences in production and use can help determine whether the power cord needs to be replaced. First, evaluate the life of the power cord based on its frequency of use and environment. Power cords that are constantly rubbed, squeezed, or exposed to moisture, heat, and dust tend to have a shorter lifespan and need to be monitored more closely and replaced regularly.

Conduct regular electrical tests. Use professional electrical testing equipment, such as a multimeter or resistance tester, to test the insulation resistance and grounding condition of the power cord. These tests can help determine whether the power cord is within operating range and needs to be replaced.

Maintain and maintain the corded power hammer normally, clean the power cord and store it promptly. Keep the power cord clean and dry, and avoid contact with grease, chemicals, or sharp objects. Check the connection part of the power cord regularly and repair or replace it if any problems are found.

Methods to determine whether the power cord of a corded power hammer needs to be replaced include visual inspection, observing the connection part, checking for twisting and knotting, and considering the use environment. Through regular inspection and testing, as well as proper maintenance and care, you can extend the life of your corded power hammer and ensure it is working properly.

Corded Rotary Hammers and Power Rotary Hammers are efficient and reliable tools. The condition of the power cord has an important impact on the performance of the tool. Therefore, the power cord should be kept in good condition at all times and damaged power cords should be replaced in time to ensure the performance of the tool. Safe for normal operation and use.

English

English Español

Español русский

русский