In recent years, lithium-ion cordless hammer drills have gained immense popularity in the construction, woodworking, and DIY sectors due to their portability, convenience, and performance. These tools offer the flexibility to work in various environments without being tethered to a power outlet, thanks to their rechargeable lithium-ion batteries. However, the battery life of these cordless hammer drills can be influenced by several factors, which users should be aware of to maximize their tool's efficiency and longevity.

1. Battery Capacity:

The battery capacity, measured in ampere-hours (Ah), is a critical factor that directly impacts the runtime of a lithium-ion cordless hammer drill. Higher capacity batteries can store more energy, allowing the tool to operate for longer periods between charges. When choosing a cordless hammer drill, opt for batteries with higher amp-hour ratings to ensure extended runtime and productivity on the job site.

2. Charging and Discharging Cycles:

The lifespan of lithium-ion batteries is determined by the number of charging and discharging cycles they undergo. Each time the battery is charged and discharged, it undergoes a certain amount of wear, leading to a gradual decrease in capacity over time. To prolong the battery life of cordless hammer drills, it is essential to follow proper charging and usage practices. Avoid frequently fully discharging the battery and instead recharge it before it reaches low levels. Additionally, use a compatible charger and avoid overcharging the battery, as this can cause overheating and damage.

3. Operating Conditions:

The operating conditions in which a lithium-ion cordless hammer drill is used can significantly impact its battery life. Extreme temperatures, both hot and cold, can affect battery performance and longevity. High temperatures can cause the battery to degrade more quickly, while cold temperatures can reduce its efficiency and capacity. To mitigate these effects, store cordless hammer drills and batteries in a cool, dry place when not in use and avoid exposing them to temperature extremes during operation.

4. Tool Usage and Workload:

The workload and intensity of use also play a crucial role in determining the battery life of lithium-ion cordless hammer drills. Heavy-duty drilling tasks that require prolonged use of the tool at maximum power can drain the battery more quickly and accelerate wear. Conversely, lighter tasks with intermittent use may extend the battery life by allowing the battery to cool down between drilling sessions. Adjusting the tool's speed and power settings to match the specific task at hand can help optimize battery performance and efficiency.

5. Maintenance and Care:

Proper maintenance and care of lithium-ion batteries are essential for maximizing their lifespan and performance. Keep the battery contacts clean and free of dirt and debris, as dirty contacts can interfere with charging and discharge processes. Additionally, periodically inspect the battery for signs of damage or wear, such as swelling, leakage, or overheating. If any abnormalities are detected, discontinue use of the battery and replace it with a new one to prevent potential safety hazards.

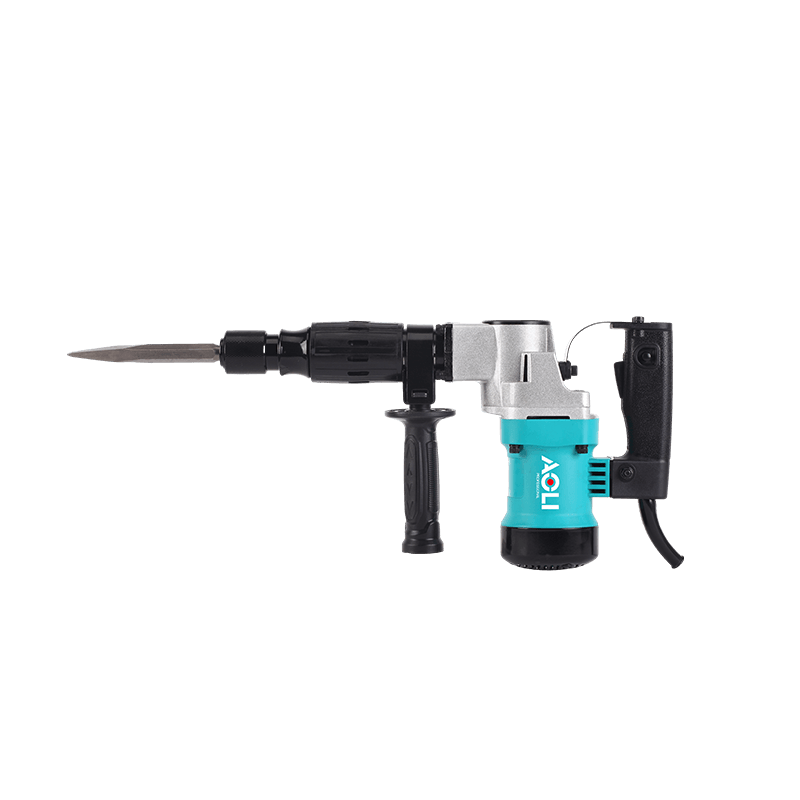

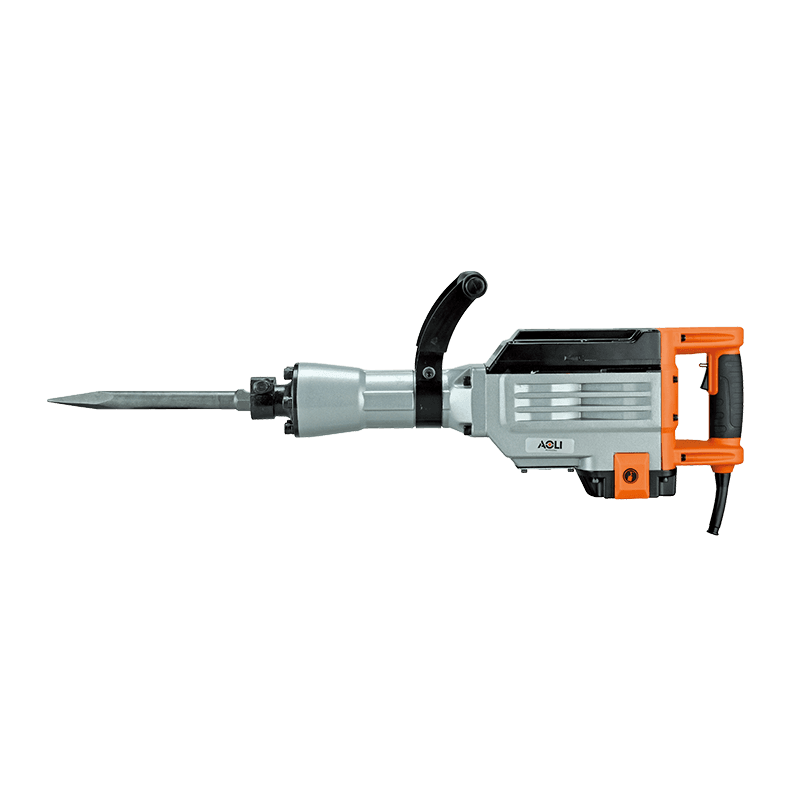

6. Hammer Drill Features:

The design and features of the cordless hammer drill itself can also influence battery life. Hammer drills with brushless motors are known for their efficiency and power savings compared to traditional brushed motors. Brushless motors reduce friction and heat generation, resulting in less strain on the battery and longer runtime. Additionally, features such as variable speed control and adjustable torque settings allow users to customize the tool's performance to match the task at hand, further optimizing battery usage and extending runtime.

The battery life of lithium-ion cordless hammer drills is influenced by various factors, including battery capacity, charging cycles, operating conditions, workload, maintenance practices, and tool features. By understanding these factors and adopting proper usage and maintenance habits, users can maximize the lifespan and performance of their cordless hammer drills, ensuring reliable and efficient operation for years to come.

English

English Español

Español русский

русский