Selecting the appropriate SDS demolition hammer drill bit is crucial for ensuring optimal performance and efficiency in your drilling and demolition tasks. With a wide variety of drill bit options available, each designed for specific materials and applications, it's essential to consider several factors to make the right choice. In this guide, we'll explore the key considerations and steps involved in selecting the ideal SDS demolition hammer drill bit for your project.

Understanding SDS System: The SDS (Special Direct System) is a standardized chuck system used in rotary hammer drills and demolition hammers. It offers quick and secure bit insertion and removal, ensuring enhanced efficiency and safety during operation.

Identifying Project Requirements: Begin by assessing the requirements of your project, including the type of material to be drilled or demolished, the size of the holes needed, and the specific tasks to be performed.

Material Compatibility: Different SDS demolition hammer drill bits are designed for specific materials, such as concrete, masonry, brick, or tile. Ensure that the drill bit you choose is compatible with the material you'll be working with to achieve optimal results.

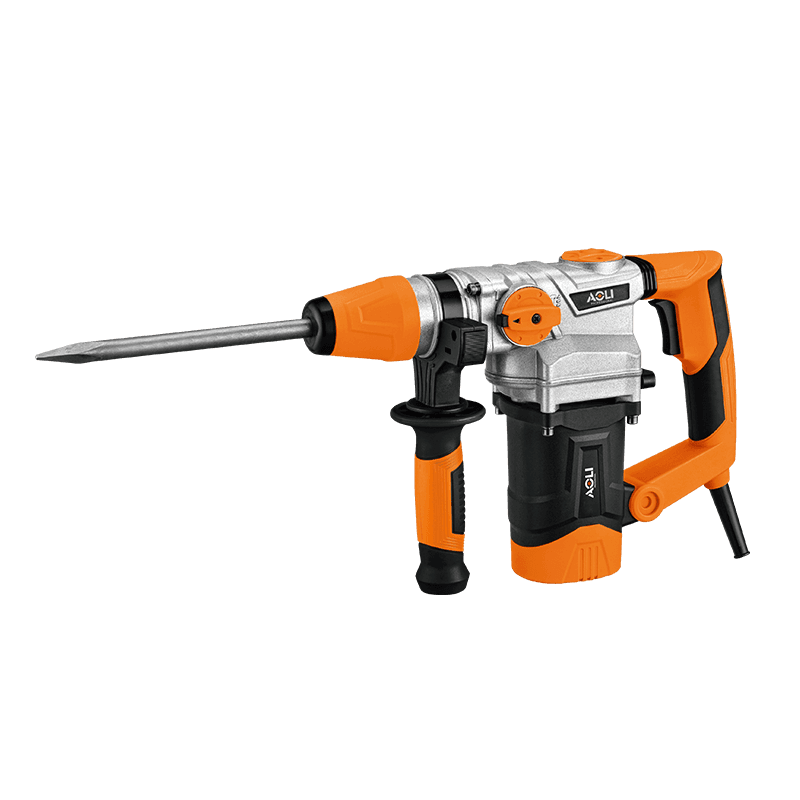

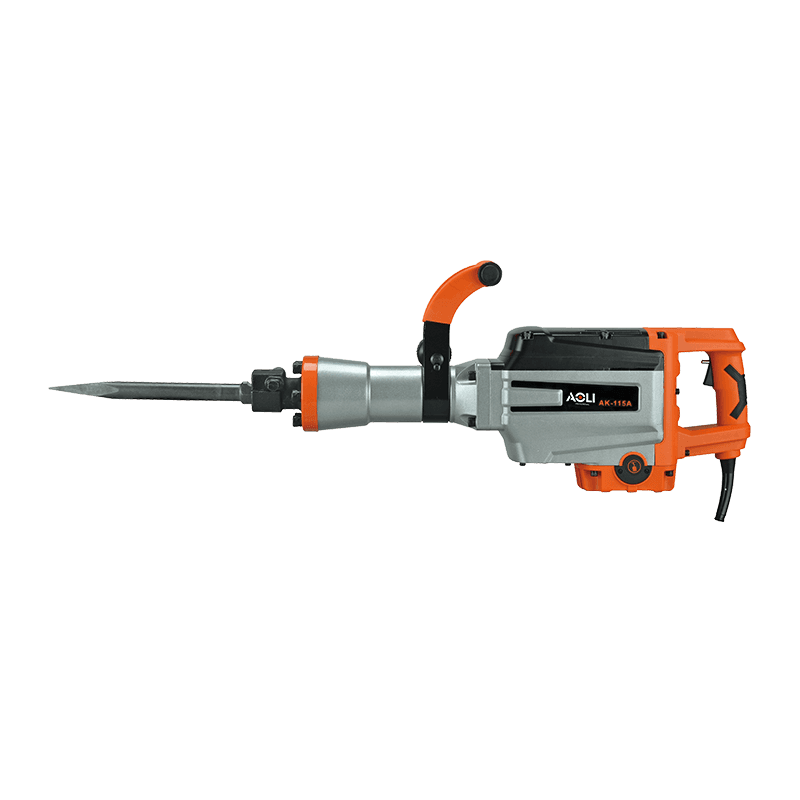

Bit Type and Configuration: SDS demolition hammer drill bits come in various types and configurations, including pointed chisels, flat chisels, gouging chisels, and wide chisels. Select the appropriate bit type based on the task at hand, whether it involves drilling, chiseling, or breaking.

Bit Size: Consider the diameter and length of the drill bit, as well as the depth and size of the holes required for your project. Choose a bit size that matches the specifications of your drilling or demolition task to ensure accurate and efficient results.

Application Specific Features: Some SDS demolition hammer drill bits are equipped with specialized features designed for specific applications, such as reinforced carbide tips for enhanced durability and performance, or flute designs for efficient dust removal during drilling.

Tool Compatibility: Ensure that the SDS demolition hammer drill bit you select is compatible with your rotary hammer drill or demolition hammer. Check the tool's chuck type (SDS-Plus, SDS-Max) and size to ensure proper fit and compatibility.

Consider Project Constraints: Take into account any constraints or limitations of the project environment, such as space restrictions, access issues, or noise regulations. Choose a drill bit that can effectively address these constraints while meeting project requirements.

Consult Manufacturer Recommendations: Refer to the manufacturer's recommendations and specifications for the SDS demolition hammer drill bits compatible with your specific tool model. Manufacturers often provide detailed guidelines and compatibility charts to assist users in selecting the right drill bits for their projects.

Test and Verify: Before proceeding with your project, test the selected SDS demolition hammer drill bit on a small sample area to ensure compatibility, performance, and safety. Make any necessary adjustments or replacements based on the results of the test.

By following these guidelines and considering the key factors mentioned above, you can confidently select the right SDS demolition hammer drill bit for your project. Remember to prioritize safety at all times and use appropriate personal protective equipment, such as safety goggles and gloves, when operating rotary hammer drills or demolition hammers. With the proper drill bit selection and careful planning, you can achieve efficient and successful outcomes in your drilling and demolition tasks.

English

English Español

Español русский

русский